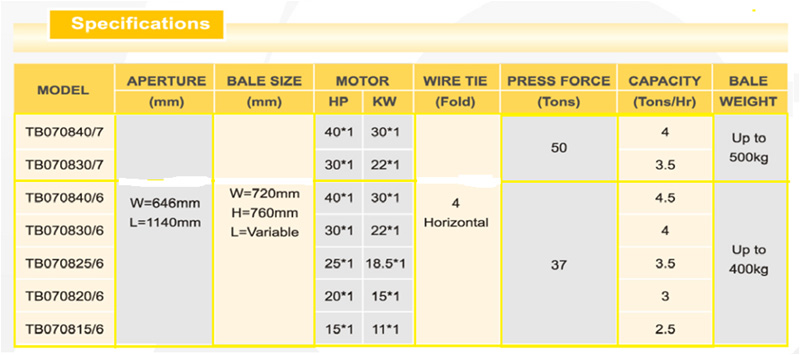

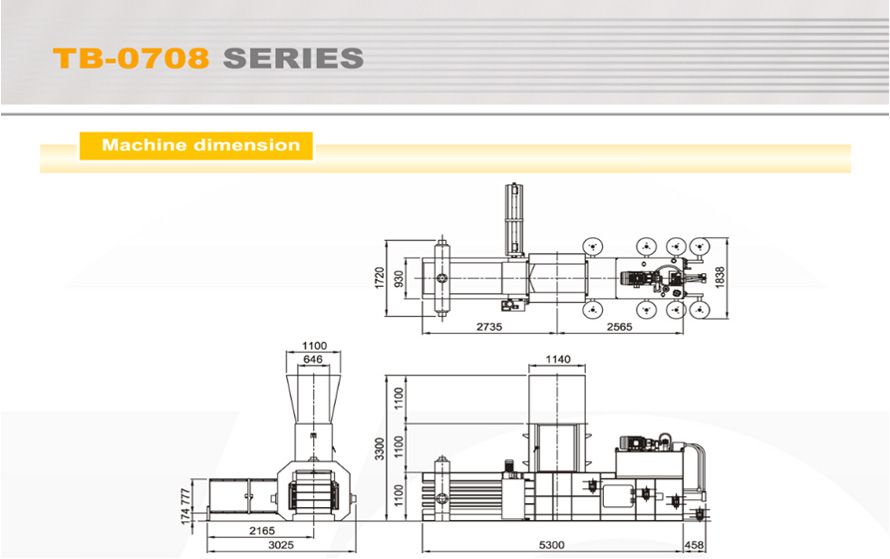

Automatic Horizontal Baling Machine TB-0708 Series

For higher production levels and automatic operation, a horizontal baler can make your waste recycling operation more efficient. Our Auto-Tie Balers can keep up with high volume applications without ever breaking a sweat.

- Suitable for recycling collector, printers, paper manufacture especially with lower capacity demand and small scale

- Can compress smaller paperboard, trimmed paper or plastic films.

- Press force up to 50 tons, capacity from 2.5~4.5 Tons per hour

- Bale size is 720(W)*760(H)*Variable(L), Bale weight can up to 500kg

- It has dewatered model which had powerful pressing forth and drainage facility.

- Can equip the conveyor, air cyclone, excavator to feed the waste materials.

- All operation and monitoring function are controlled through a programmable logic controller(PLC)

- The position of operation panel and shape of hopper can be modified to satisfy the real demand of customer.

- Exclusive auto-tier system

- The strong and rigid structure is reliable and optimum for less maintenance.

Result 1 - 5 of 5

Result 1 - 5 of 5

English

English